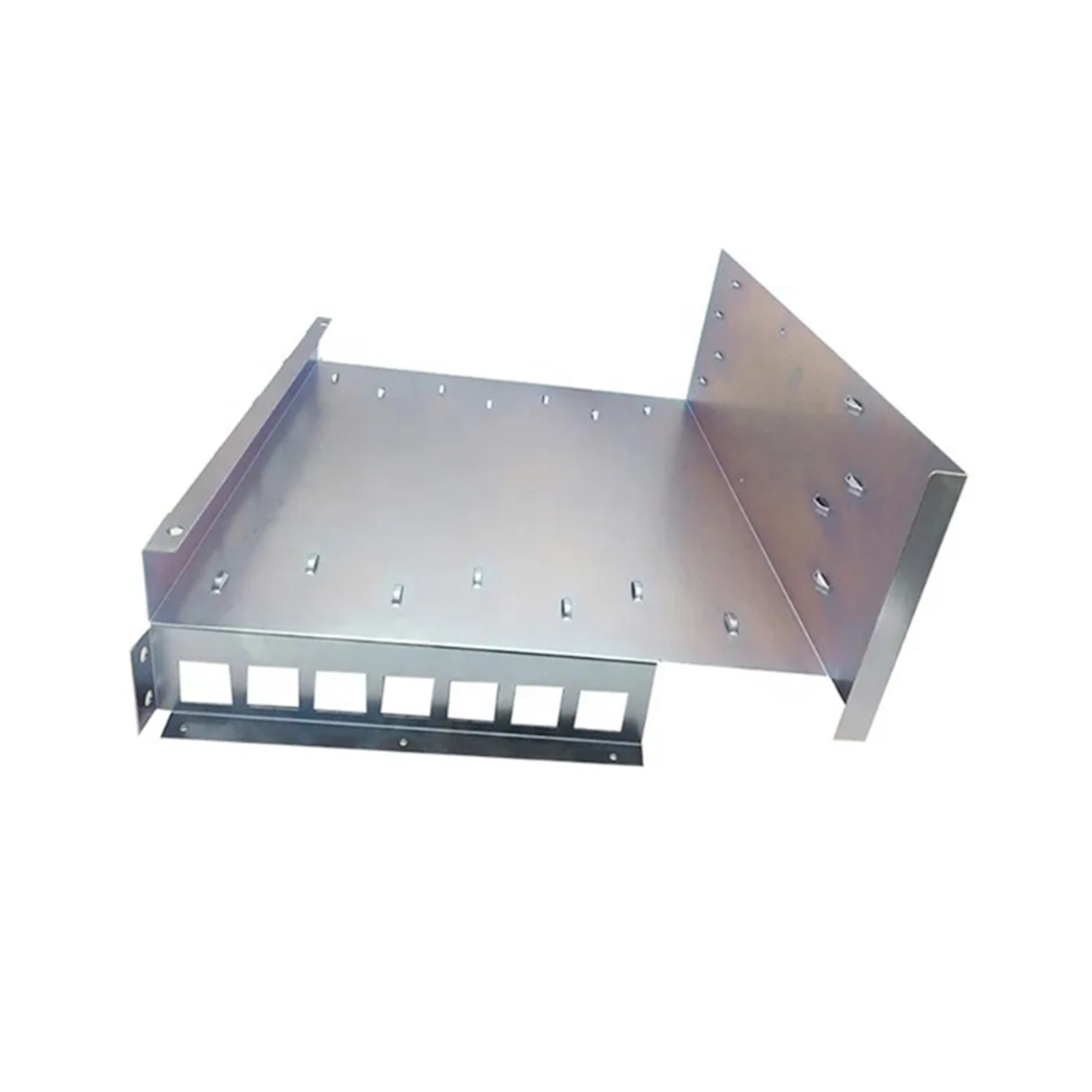

Kev cai aluminium hlau dabtsi yog khoov stamping qhov chaw galvanized bracket

Kev piav qhia

| Yam khoom | customized khoom | |||||||||||

| One-Stop Service | Pwm txoj kev loj hlob thiab tsim-xa cov qauv-batch ntau lawm-kev tshuaj xyuas-nto kho- ntim-xa. | |||||||||||

| Txheej txheem | stamping, dabtsi yog khoov, sib sib zog nqus daim duab, ntawv hlau fabrication, vuam, laser txiav thiab lwm yam. | |||||||||||

| Khoom siv | carbon steel, stainless hlau, txhuas, tooj liab, galvanized hlau thiab lwm yam. | |||||||||||

| Qhov ntev | raws li tus neeg siv khoom kos duab lossis qauv. | |||||||||||

| Ua kom tiav | Txau painting, electroplating, kub-dip galvanizing, hmoov txheej, electrophoresis, anodizing, blackening, thiab lwm yam. | |||||||||||

| Kev thov cheeb tsam | Auto Parts, Agricultural Machinery Parts, Engineering Machinery Parts, Siv Engineering Parts, Garden Accessories, Eco-friendly Machinery Parts, Nkoj Yam, aviation Parts, Pipe Fittings, Hardware Tool Parts, Toy Part, electronics, etc. | |||||||||||

Qhov zoo

1. Ntau tshaj 10 xyoontawm kev lag luam txawv teb chaws.

2. Muabib-stop servicelos ntawm pwm tsim rau cov khoom xa tuaj.

3. Lub sijhawm xa khoom sai, txog30-40 hnub. Hauv Tshuag hauv ib lub lis piam.

4. Kev tswj xyuas nruj thiab tswj cov txheej txheem (ISOcertified chaw tsim tshuaj paus thiab Hoobkas).

5. Ntau tus nqi tsim nyog.

6. Kev tshaj lij, peb lub Hoobkas muajntau tshaj 10xyoo ntawm keeb kwm nyob rau hauv lub tshav pob ntawm hlau stamping sheet hlau.

Kev tswj kom zoo

Vickers hardness ntsuas.

Profile ntsuas ntsuas.

Spectrograph ntsuas.

Peb qhov kev sib koom tes.

Daim duab xa khoom

Txheej txheem ntau lawm

01. Pwm tsim

02. Pwm ua

03. Hlau txiav ua

04. Pwm kho cua sov

05. Pwm sib dhos

06. Pwm debugging

07. Deburring

08. electroplating

09. Kev kuaj khoom

10. Pob

Khoom zoo

Qhov zoo ntawm aluminium stamping qhov chaw yog qhov tseem ceeb hauv cov hauv qab no:

1. Cov khoom zoo heev: Txhuas muaj qhov ceev qis thiab lub teeb yuag, tab sis muaj kev sib dhos zoo thiab machinability, yog li nws haum rau stamping ua. Nyob rau tib lub sijhawm, aluminium alloy stamping qhov chaw muaj cov yas zoo heev thiab tuaj yeem kos rau hauv filaments thiab dov rau hauv foils, uas tuaj yeem ua tau raws li cov qauv tsim ntawm ntau yam duab thiab cov qauv.

2. Zoo corrosion kuj: Aluminium alloys qhia zoo corrosion kuj nyob rau hauv chav tsev kub thiab tsis yooj yim cuam tshuam los ntawm cov tshuaj xws li acids thiab alkalis. Yog li ntawd, aluminium stamping qhov chaw tuaj yeem tswj kev ua haujlwm ruaj khov txawm tias nyob rau hauv qhov chaw hnyav.

3. Zoo hluav taws xob thiab thermal conductivity: Aluminium alloys muaj cov hluav taws xob zoo thiab thermal conductivity, uas ua rau txhuas stamping qhov chaw dav siv hauv electronics, khoom siv hluav taws xob thiab lwm yam.

4. Cov txheej txheem ntau lawm: Cov txheej txheem stamping tuaj yeem tsim cov khoom siv txhuas stamping qhov chaw uas muaj kev ua haujlwm siab thiab tus nqi qis. Nyob rau tib lub sijhawm, cov txheej txheem stamping kuj tuaj yeem ua kom qhov tseeb qhov tseeb thiab qhov zoo ntawm qhov chaw, ua tau raws li qhov yuav tsum tau muaj ntawm qhov siab thiab qhov zoo.

5. Kev siv ntau yam: Aluminium stampings yog dav siv hauv kev tsim tsheb, kev tsim khoom siv hauv tsev, khoom siv hluav taws xob, kev tsim tshuab, khoom siv elevator, thiab aerospace. Piv txwv li, lawv tuaj yeem siv rau hauv kev tsim cov plhaub ntawm lub cev, lub qhov rooj vaj huam sib luag, lub tshuab ntxhua khaub ncaws, lub tshuab ntxhua khaub ncaws, lub tshuab hluav taws xob, cov hlua khi, lub tsheb of elevator, cov lus qhia kev tsheb ciav hlau, lub davhlau ya nyob twg thiab lwm yam khoom siv.

Aluminium alloy nws tus kheej muaj cov yam ntxwv ntawm lub teeb, lub zog, kev ua haujlwm yooj yim thiab kev tiv thaiv corrosion, uas ua rau nws cov khoom zoo rau kev tsim khoom. Los ntawm cov txheej txheem stamping, txhuas stampings nrog cov duab nyuaj thiab qhov ntev yuav raug tsim.

FAQ

Q1: Yog tias peb tsis muaj cov duab kos, peb yuav ua li cas?

A1: Txhawm rau pab peb kom luam tawm lossis muab cov kev daws teeb meem zoo tshaj rau koj, ua siab zoo xa koj cov qauv rau peb cov chaw tsim khoom. Xa peb cov duab lossis cov duab kos uas suav nrog qhov loj me hauv qab no: thickness, ntev, qhov siab, thiab dav. Yog tias koj tso qhov kev txiav txim, CAD lossis 3D cov ntaub ntawv yuav raug tsim rau koj.

Q2: Dab tsi ua rau koj sib nrug ntawm lwm tus?

A2: 1) Peb Qhov Kev Pabcuam Zoo Tshaj Plaws Yog tias peb tau txais cov ntaub ntawv nthuav dav hauv cov sijhawm ua haujlwm, peb yuav xa cov lus hais hauv 48 teev.

2) Peb hloov pauv sai rau kev tsim khoom Peb lav 3-4 lub lis piam rau kev tsim khoom rau kev txiav txim tsis tu ncua. Raws li lub Hoobkas, peb tuaj yeem lav lub hnub xa khoom raws li tau teev tseg hauv daim ntawv cog lus raug cai.

Q3: Puas muaj peev xwm nrhiav tau qhov zoo ntawm kuv cov khoom muag yam tsis tau mus ntsib koj lub lag luam?

A3: Peb yuav muab lub sijhawm ua tiav nrog rau cov ntawv tshaj tawm txhua lub limtiam uas suav nrog cov duab lossis cov yeeb yaj kiab qhia txog qhov xwm txheej ntawm machining.

Q4: Nws puas tuaj yeem tau txais cov qauv lossis kev txiav txim rau ob peb yam khoom nkaus xwb?

A4: Vim tias cov khoom yog tus kheej thiab yuav tsum tau ua, peb yuav them tus qauv. Txawm li cas los xij, yog tias tus qauv tsis kim dua li qhov kev txiav txim ntau, peb yuav rov them tus nqi coj mus kuaj.