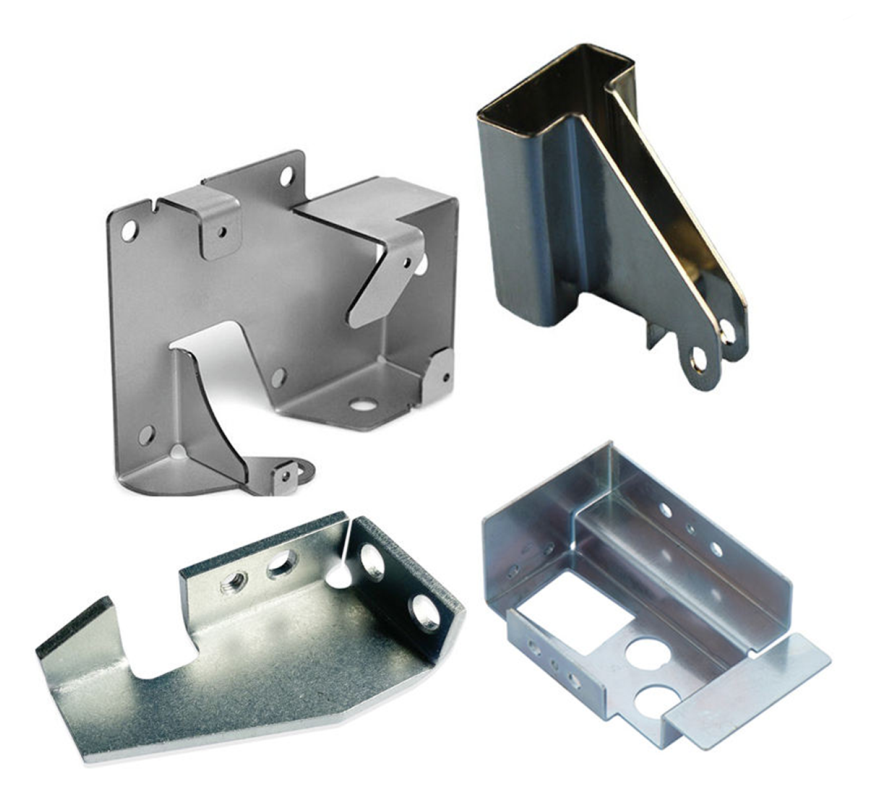

Kev Cai Hlau Stamping Service

Peb saib ntawm txhua yam khoom thiab cov txheej txheem los ntawm qhov pom ntawm cov khoom siv qis tshaj plaws (tsis yog yuav tsum tsis meej pem nrog qhov zoo tshaj plaws) ua ke nrog cov txheej txheem ntau lawm uas tuaj yeem tshem tawm ntau npaum li qhov tsis muaj nuj nqis ua haujlwm thaum ua kom ntseeg tau tias cov txheej txheem tuaj yeem muab100% khoom zoo.

Xyuas kom tseeb tias txhua yam khoom ua tau raws li qhov yuav tsum tau ua, kev ua siab ntev, thiab polishing nto.Saib xyuas qhov kev nce qib ntawm machining.Peb qhov kev tswj xyuas zoo tau txais ISO 9001: 2015 thiab ISO 9001: 2000 zoo system ntawv pov thawj.

Txij li xyoo 2016, nws tau xa tawm mus rau lwm lub tebchaws thaum tseem muabOEM thiab ODM kev pabcuam.Yog li ntawd, nws tau txais kev ntseeg siab ntawmntau tshaj 100 tus neeg siv khoomob leeg hauv tsev thiab txawv teb chaws thiab tsim kev sib raug zoo nrog lawv.

Lub lag luam ua haujlwm30cov kws tshaj lij thiab cov kws tshaj lij thiab muaj ib4000㎡Hoobkas.

Lub rhiav muaj 32 punch presses ntawm ntau yam tonnages, qhov loj tshaj plaws ntawm uas yog 200 tons, thiab tshwj xeeb nyob rau hauv muab cov neeg muas zaub nrog ntau yam customized stamping khoom.

Peb muab tag nrho cov kev kho mob saum npoo uas koj xav tau los tsim cov khoom tiav zoo, suav nrog sandblasting, polishing, anodizing, electroplating, laser etching, thiab painting.

Tuam txhab Profile

Lub 2016-tsim Ningbo Xinzhe Hlau Khoom Co., Ltd. muaj ntau tshaj 7 xyoo ntawm kev txawj ntse tsimkev cai hlau stamping. Precision stampingthiab loj tsim ntawm intricate stamping Cheebtsam yog qhov tseem ceeb ntawm peb cov chaw.Nws muaj tswv yim daws teeb meem rau koj cov khoom nyuaj raws li nws cov refined ntau lawm txoj kev thiab tej-edge industrial technologies.Nyob rau hauv lub xyoo, peb tau ua raws li lub lag luam tenet ntawm " ciaj sia taus los ntawm zoo, kev loj hlob los ntawm lub koob npe nrov", thiab tau cog lus los muab koj. nrog cov khoom zoo thiab cov kev pabcuam zoo.Nrog cov kws tshaj lij thiab pab pawg tsim qauv thiab kev tswj hwm, los ntawm cov khoom tsim, pwm tsim, molding rau cov khoom sib dhos, txhua qhov txuas thiab cov txheej txheem tau raug soj ntsuam nruj me ntsis thiab tswj.

Cov neeg tsim khoom sab saum toj ntawm qhov tseebkhoom siv kho mob stamping qhov chawhauv Suav teb

Cov cuab yeej kho mob stampingyog qhov tshwj xeeb tshaj plaws tsim los ua kom tau raws li cov kev cai tshwj xeeb ntawm kev kho mob.Cov khoom no yog tsim los ntawm txoj kev stamping, uas siv hydraulic presses kom nruj siab rau cov ntawv hlau kom zoo thiab deform rau hauv cov duab thiab qhov ntau thiab tsawg.Rau cov cuab yeej kho mob lawv yog ib feem ntawm kev ua haujlwm kom raug, qhov tseeb thiab qhov tseeb ntawm cov khoom no yog qhov tseem ceeb.

Tsim, prototyping, kuaj, thiab serial manufacturing yog tag nrho cov kauj ruam hauv cov txheej txheem intricate ntawm cov cuab yeej kho mob stamping.Ib qho qauv 3D ntawm cov khoom siv kho mob uas yuav tsim tau yog tsim thaum lub sij hawm tsim thiab siv los tsim cov qauv.Kev ntsuam xyuas yog ua tiav ntawm cov qauv kom paub tseeb tias lawv ua raws li txhua qhov kev xav tau.

Peb lub lag luam tshwj xeeb hauv kev tsim cov micro sib sib zog nqus nqus stamping thiab precision stamping, uas tuaj yeem ua kom tau raws li qhov tseeb.kev kho mob stamping qhov chaw!

Ua tus tsim tawm ntawmnws pib stamping qhov chaw hauv Suav teb

Tam sim no, hlau stamping khoom yog ua hauj lwm nyob rau hauv ntau yam kev lag luam, nrog rau cov uas cuam tshuam nrog autos, cov khoom siv hauv tsev, kev tsim kho, thiab lwm yam. Ntawm cov no, cov hlau stamping kev lag luam tau pab rautsheb stampingyog qhov tseem ceeb.

Lub peev xwm sai sai tsim cov khoom siv ntau yog ib qho ntawm cov txiaj ntsig tseem ceeb ntawm lub tsheb stamping.Qhov no yog qhov tseem ceeb rau kev lag luam tsheb, raws li cov neeg tsim khoom tsim tawm kaum tawm txhiab lub tsheb txhua xyoo.Lawv tuaj yeem ua tiav qhov nrawm thiab ua tau zoo nrogtsheb stamping, uas txo cov nqi thiab txhawb kev tsim khoom.Lwm qhov txiaj ntsig ntawm lub tsheb stampings yog lawv cov qib siab ntawm qhov tseeb.

Cov tshuab stamping yog tsim los txiav thiab ua cov hlau rau qhov kev ntsuas qhov tseeb uas xav tau rau txhua yam khoom, lav tias txhua yam khoom zoo ib yam li lwm yam.Kev ntseeg ntawm lub tsheb thiab kev nyab xeeb nyob ntawm qhov raug.

Peb tam sim no muaj kev sib txuas ua lag luam nrog ntau lub tuam txhab muaj npe nrov,xws li Ford thiab Volkswagen.Peb paub tseeb tias peb cov tshuab stamping muaj zog tuaj yeem ua rau cov neeg siv khoom lag luam muaj kev sib tw ua tsaug rau peb cov kws tshaj lij hauv stamping tuag tsim thiab kev tswj kom zoo.Peb cov neeg ua haujlwm R & D muaj peev xwm tuaj yeem ua tiav txhua qhov kev thov tshwj xeeb los ntawm cov neeg siv khoom.Tsuas xa peb CAD lossis 3D pem teb layout, thiab peb yuav saib xyuas txhua yam kom txog thaum koj qhov kev txiav txim pom.Koj raug caw los tshuaj xyuas cov khoom siv hlau zoo thiab peb cov neeg siv khoom.

Tuam Tshoj tus thawj manufacturers ntawmhluav taws xob accessories stamping

Xinzhe muab cov khoom zoo, txiav-ntug rau ntau tus neeg siv khoom hauv kev sib txuas lus.Peb yog cov chaw tsim khoom ntseeg siab ntawm ntau yam khoom siv hluav taws xob.

Txhawm rau tsim cov khoom siv hluav taws xob zoo tshaj plaws stamping qhov chaw, nws yog thawj zaug uas yuav tsum tau ua tiav cov txheej txheem stamping tiav.Qhov no suav nrog kev tsim cov pwm tsim nyog, xaiv cov khoom zoo raw khoom, tswj kom tsim nyog stamping kub thiab siab, thiab lwm yam. Cov txheej txheem stamping precision yuav ua kom cov khoom raug, kev ntseeg tau thiab ua raws li cov lus qhia tshwj xeeb.

Lwm lub ntsiab tseem ceeb yog kev tswj tag nrho thaum ntxuav thiab ntim khoom.Kev huv huv yog ib qho tseem ceeb ntawm kev txiav txim siab zoo ntawm cov khoom lag luam stamped rau cov khoom siv hluav taws xob.Thaum lub sij hawm tsim khoom, cov khoom raug cuam tshuam los ntawm ntau yam impurities thiab cov kab mob, nrog rau cov roj, oxide txheej thiab hmoov av.Yog li ntawd, cov khoom yuav tsum tau ntxuav kom tob thiab kaw thiab noo noo-pov thawj thaum ntim.

Txhawm rau ua kom tiav, rau kev tsim cov khoom siv hluav taws xob zoo tshaj plaws stamping cov khoom, nws yog ib qho tsim nyog los xaiv lub tuam txhab stamping nrog kev nplua nuj thiab kev siv tshuab.Peb lub tuam txhab yuav tsum muaj peev xwm muab cov txheej txheem tiav ntawm cov txheej txheem stamping kev daws teeb meem kom ntseeg tau tias cov khoom tsim tau raws li cov lus qhia tshwj xeeb, muaj kev ua haujlwm siab thiab muaj kev ntseeg siab.