Kev cai hlau sib sib zog nqus kos qhov chaw

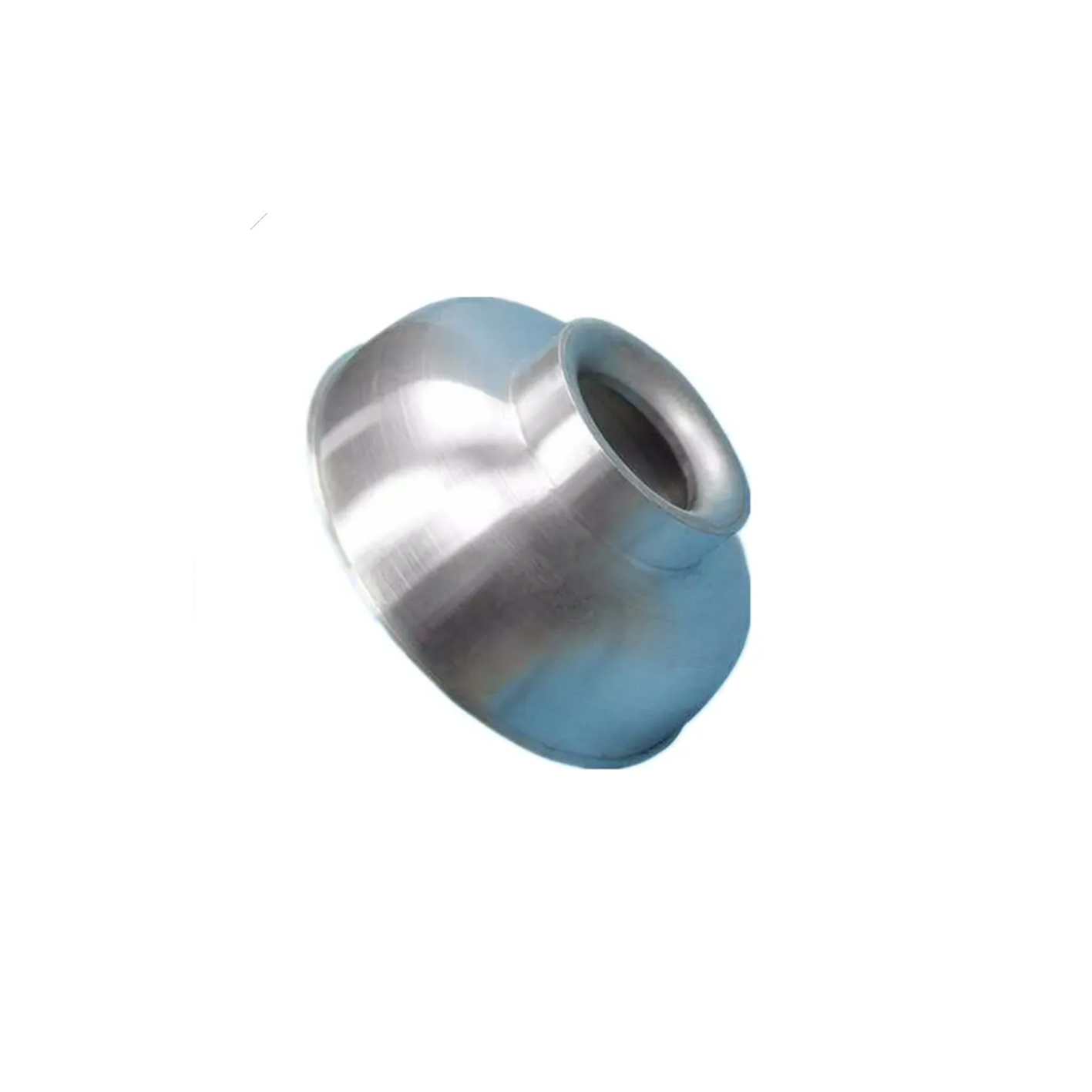

Nrog rau txoj kev loj hlob ntawm tib neeg, stamping qhov chaw tau tsim nyob rau hauv ntau yam lag luam, thiab stamping qhov chaw tuaj yeem pom nyob txhua qhov chaw hauv lub neej txhua hnub. Muaj ntau ntau yam ntawm stamping workpieces, uas yog siv nyob rau hauv txhua qhov chaw ntawm lub neej, thiabhlau sib sib zog nqus nqus qhov chaw yog ib tug ntawm lawv. Hlaudaim duab sib sib zog nqusstampingyog siv lub tshuab stamping los deform phaj zoo li cov ntaub ntawv hlau rau hauv cylindrical, rectangular, trapezoidal, spherical thiab conical qhov chaw los ntawm kev siv cov txheej txheem ntawm rub lub nplhaib lossis hlau pwm. Yog tias ua ke nrog lwm cov txheej txheem stamping, ntau qhov nyuaj thiab meej tuaj yeem tsim tau. Feem ntau, cov ductility ntawm cov hlau yuav cuam tshuam ncaj qha rau kev tsim khoom thiab qhov zoo ntawm kev sib sib zog nqus nqus, yog li cov hlau flakes feem ntau yog siv los ua raw khoom rau stamping. Cov tob koshauvib feemstxheej txheem yog txheej txheem tsim tshwj xeeb zoo nkauj vim nws txuag cov peev txheej. Cov ntaub ntawv tensile feem ntau suav nrog aluminium alloy, steel, zinc, tooj liab thiab lwm yam hlau.-

Customized precision kos hlau qhov chaw ua khoom

-

Kev cai Sheet Hlau Hlau Txhuas thiab tooj liab Stamping Cheebtsam

-

Customized Heavy Carbon Steel Sheet Hlau Stamping Sib sib zog nqus kos qhov chaw

-

Kev Cai Stamping Teeb Lub Cev Lub Cev rau Ceiling Lighting Hoobkas

-

Customized aluminium hau rau ntau lub thawv ntim thiab lub raj mis hlau

-

Kev Cai Hlau Stamping Parts Deep Drawn Steel Sheet Hlau Sib Nqus Drawing

-

OEM kev cai ntawv hlau stamping qhov chaw ntawv hlau stamping Cheebtsam

-

OEM Hlau carbon steel Sib sib zog nqus nqus nias Cheebtsam ntawm tus nqi sib tw

-

Custom Sheet Hlau Fabrication Hlau Yeeb Nkab Kawg Caps

-

Customized high-precision sib sib zog nqus-draw tshav kub shield nws pib qhov chaw

-

chaw tsim tshuaj paus customized stainless hlau Sheet Hlau sib sib zog nqus nqus qhov chaw

-

OEM ODM zoo stainless hlau stamping sib sib zog nqus nqus hlau ib feem