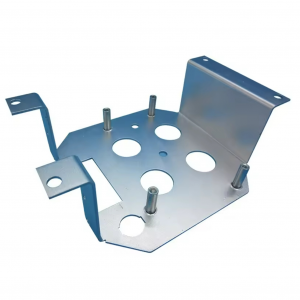

Customized precision bracket stainless hlau ntawv hlau stamping qhov chaw

Kev piav qhia

| Yam khoom | customized khoom | |||||||||||

| One-Stop Service | Pwm txoj kev loj hlob thiab tsim-xa cov qauv-batch ntau lawm-kev tshuaj xyuas-nto kho- ntim-xa. | |||||||||||

| Txheej txheem | stamping, dabtsi yog khoov, sib sib zog nqus daim duab, ntawv hlau fabrication, vuam, laser txiav thiab lwm yam. | |||||||||||

| Khoom siv | carbon steel, stainless hlau, txhuas, tooj liab, galvanized hlau thiab lwm yam. | |||||||||||

| Qhov ntev | raws li tus neeg siv khoom kos duab lossis qauv. | |||||||||||

| Ua kom tiav | Txau painting, electroplating, kub-dip galvanizing, hmoov txheej, electrophoresis, anodizing, blackening, thiab lwm yam. | |||||||||||

| Kev thov cheeb tsam | Auto Parts, Agricultural Machinery Parts, Engineering Machinery Parts, Siv Engineering Parts, Garden Accessories, Eco-friendly Machinery Parts, Nkoj Yam, aviation Parts, Pipe Fittings, Hardware Tool Parts, Toy Part, electronics, etc. | |||||||||||

Muaj peev xwm

Txhawm rau ua kom tau raws li qhov xav tau ntawm cov neeg siv khoom, Xinzhe muaj cov chav ua haujlwm puv ntoob hauv tsev rau kev tsim, engineering, thiab tsim ntau hom hlau stamping tuag, suav nrog kev sib xyaw ua ke, nce qib, kos duab, thiab cov cuab yeej ua qauv.

Qhov tseem ceeb tshaj plaws, peb cov cuab yeej siv nyiaj txiag zoo, zoo hlau stamping txo cov nqi tsim khoom thiab kev ua haujlwm. Rau lub sijhawm ntawm cov phiaj xwm stamping, peb kuj tswj thiab kho tag nrho peb cov neeg siv khoom tuag yam tsis muaj nqi ntxiv rau lawv.

1. Cov cuab yeej hloov kho sai kom suav nrog kev hloov pauv hauv engineering.

2. Cov khoom siv zoo tshaj plaws.

3. kev txawj ntse hauv kev tsim cov cuab yeej.

4. Cov kws tshaj lij thiab cov cuab yeej txawj ntse uas muaj kev paub txog kev stamping.

5. Siv Advanced Wire EDM, koj tuaj yeem txiav koj cov khoom kom meej thiab pheej yig.

Kev tswj kom zoo

Vickers hardness ntsuas.

Profile ntsuas ntsuas.

Spectrograph ntsuas.

Peb qhov kev sib koom tes.

Daim duab xa khoom

Txheej txheem ntau lawm

01. Pwm tsim

02. Pwm ua

03. Hlau txiav ua

04. Pwm kho cua sov

05. Pwm sib dhos

06. Pwm debugging

07. Deburring

08. electroplating

09. Kev kuaj khoom

10. Pob

Electrophoresis txheej txheem

Cov txheej txheem electrophoresis feem ntau suav nrog cov kauj ruam hauv qab no:

1. Kev ua qauv: Xaiv ib qho qauv tsim nyog thiab ua cov txheej txheem pretreatment uas tsim nyog raws li cov qauv qauv, xws li kev cuam tshuam ntawm tes, protein solubilization, thiab lwm yam. Ua ntej yuav ntxiv qhov tsis zoo rau cov qauv, nws yuav tsum tau centrifuged kom tshem tawm impurities lossis precipitates.

2. Kev npaj ntawm qhov tsis: Buffer ua lub luag haujlwm hauv kev tswj pH stability, muab ionic conductivity thiab diluting cov qauv thaum lub sij hawm sim electrophoresis. Thaum npaj cov buffers, reagents yuav tsum raug ntsuas kom raug thiab diluted hauv qhov tseeb proportions.

3. Kev npaj ntawm electrophoresis tank thiab electrodes: Ntxuav lub electrophoresis tank thiab electrodes kom ntseeg tau tias tsis muaj impurities nyob. Xyuas tias cov electrodes nyob rau hauv nruj kev sib cuag nrog lub tank phab ntsa thiab hais tias cov kab txuas tsis tawg los yog luv luv.

4. Npaj cov xim: Dissolve cov xim electrophoretic nyob rau hauv dej los ua ib tug uniform thiab ruaj khov ncua kev kawm ntawv. Cov txheej txheem ntawm txheej yuav tsum raug xaiv raws li qhov yuav tsum tau ua ntawm cov khoom ua haujlwm thiab daim ntawv thov daim teb, thiab feem ntau suav nrog cov resin, hnyav, curing agent, muab tub lim, thiab lwm yam. Tsis tas li ntawd, ib co additives xws li defoaming agents thiab leveling agents tuaj yeem muab ntxiv.

5. Teem lub tank electrophoresis: Muab lub tank electrophoresis uas muaj cov xim pleev xim rau hauv cov khoom siv electrophoresis, thiab txuas cov electrodes zoo thiab tsis zoo rau cov khoom siv hluav taws xob. Qhov zoo electrode txuas nrog lub phaj hlau hauv lub tank electrophoresis, thiab qhov tsis zoo electrode txuas nrog lub workpiece los ua kom muaj hluav taws xob nyob rau hauv qhov kev txiav txim ntawm qhov hluav taws xob.

6. Kho cov xim tsis muaj xim: Raws li qhov yuav tsum tau ua ntawm lub workpiece thiab xim, kho cov xim tsis muaj nyob hauv lub tank electrophoresis, xws li concentration, pH nqi, kub thiab voltage, thiab lwm yam.

7. Sample loading: Ntxiv cov khoom mus kuaj rau hauv lub tank npaj electrophoresis rau kev sib cais. Thaum thauj cov qauv, yuav tsum tau saib xyuas kom tsis txhob muaj cua nkag mus rau hauv cov gel kom tsis txhob cuam tshuam rau kev sib cais. Txiav txim siab qhov tsim nyog loading npaum li cas raws li tus qauv loj thiab concentration. Ntau dhau lossis tsawg dhau tuaj yeem cuam tshuam cov txiaj ntsig kev sim.

8. Pib electrophoresis: Muab cov txheej txheem ua haujlwm rau hauv lub tank electrophoresis thiab xyuas kom meej tias lub workpiece nyob rau hauv tiav kev sib cuag nrog cov xim. Tig lub zog, ua rau cov khoom siv hluav taws xob los yog cov ions hauv cov xim txav mus rau thiab tso rau ntawm qhov chaw ntawm lub workpiece nyob rau hauv qhov kev txiav txim ntawm hluav taws xob teb.

9. Coating curing: Tom qab txheej txheej ntawm lub workpiece mus txog qhov yuav tsum tau tuab, nqa lub workpiece tawm ntawm lub tank electrophoresis thiab xa mus rau lub qhov cub los yog cua qhuav kom solidify txheej.

Cov saum toj no yog cov kauj ruam dav dav ntawm cov txheej txheem electrophoresis. Cov haujlwm tshwj xeeb tuaj yeem hloov kho vim muaj cov cuab yeej sib txawv thiab cov txheej txheem. Thaum lub sij hawm tag nrho cov txheej txheem electrophoresis, ntau yam tsis muaj thiab kev khiav hauj lwm cov kauj ruam yuav tsum tau nruj me ntsis tswj kom cov khoom zoo thiab stability.

Peb Kev Pabcuam

1. Pab pawg kws tshaj lij R & D: Txhawm rau pab koj ua lag luam, peb cov engineers tsim cov qauv tsim tshiab rau koj cov khoom.

2. Pab Pawg Saib Xyuas Zoo: Txhua yam khoom raug kuaj xyuas kom paub tseeb tias nws ua haujlwm zoo ua ntej nws xa tuaj.

3. Cov neeg ua haujlwm muaj peev xwm logistics - tus kheej ntim khoom thiab tshawb xyuas sai tau lees tias cov khoom muaj kev nyab xeeb txog thaum nws ncav cuag koj.

4. Ib tus neeg ua haujlwm tom qab yuav khoom tus kheej uas muab cov neeg siv khoom sai, kev pabcuam kws tshaj lij nyob ib puag ncig.

5.Ib tug neeg muag khoom txawj ntse yuav muab cov kev paub zoo tshaj plaws rau koj los pab koj ua lag luam nrog cov neeg siv khoom zoo dua.