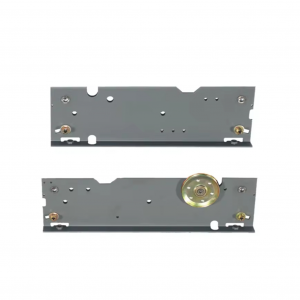

of the elevator leveling flat contact switch metal contact piece

Kev piav qhia

| Yam khoom | customized khoom | |||||||||||

| One-Stop Service | Pwm txoj kev loj hlob thiab tsim-xa cov qauv-batch ntau lawm-kev tshuaj xyuas-nto kho- ntim-xa. | |||||||||||

| Txheej txheem | stamping, dabtsi yog khoov, sib sib zog nqus daim duab, ntawv hlau fabrication, vuam, laser txiav thiab lwm yam. | |||||||||||

| Khoom siv | carbon steel, stainless hlau, txhuas, tooj liab, galvanized hlau thiab lwm yam. | |||||||||||

| Qhov ntev | raws li tus neeg siv khoom kos duab lossis qauv. | |||||||||||

| Ua kom tiav | Txau painting, electroplating, kub-dip galvanizing, hmoov txheej, electrophoresis, anodizing, blackening, thiab lwm yam. | |||||||||||

| Kev thov cheeb tsam | Of elevator accessories, engineering machinery accessories, siv engineering accessories, pib accessories, ib puag ncig tiv thaiv machinery accessories, nkoj accessories, aviation accessories, yeeb nkab fittings, kho vajtse cuab yeej accessories, khoom ua si accessories, hluav taws xob accessories, thiab lwm yam. | |||||||||||

Qhov zoo

1. Ntau tshaj10 xyoontawm kev lag luam txawv teb chaws.

2. Muabib-stop servicelos ntawm pwm tsim rau cov khoom xa tuaj.

3. Lub sijhawm xa khoom sai, txog 25-40 hnub.

4. Kev tswj xyuas nruj thiab tswj cov txheej txheem (ISO 9001 Daim ntawv pov thawjcertified chaw tsim tshuaj paus thiab Hoobkas).

5. Factory khoom ncaj qha, tus nqi sib tw ntau dua.

6. Kev tshaj lij, peb lub Hoobkas pabcuam cov ntawv hlau ua kev lag luam thiab tau sivlaser txiavtechnology rau ntau tshaj10 xyoo.

Kev tswj kom zoo

Vickers hardness ntsuas.

Profile ntsuas ntsuas.

Spectrograph ntsuas.

Peb qhov kev sib koom tes.

Daim duab xa khoom

Txheej txheem ntau lawm

01. Pwm tsim

02. Pwm ua

03. Hlau txiav ua

04. Pwm kho cua sov

05. Pwm sib dhos

06. Pwm debugging

07. Deburring

08. electroplating

09. Kev kuaj khoom

10. Pob

Daim ntawv sib tiv tauj yog dab tsi?

Cov ntawv hlau sib txuas ntawm lub tiaj tus hloov pauv yog ib qho tseem ceeb hauv kev sib txuas sib txuas. Nws yog feem ntau siv hauv kev sib cuag ntawm cov khoom siv hluav taws xob thiab hluav taws xob.

Muaj nuj nqi thiab lub luag haujlwm

Kev ua haujlwm zoo: Cov ntawv hloov ntawm cov ntawv hlau ua haujlwm ua tus neeg xyuas pib hauv Circuit Court. Txhawm rau kom kaw tag nrho lossis txiav tawm lub voj voog, tam sim no raug xa mus los ntawm daim ntawv tiv tauj los ntawm ib qho hluav taws xob mus rau lwm qhov thaum lub hloov pauv tau nias.

Elastic rov qab quab yuam: Feem ntau muaj qee qhov elasticity nyob rau hauv daim ntawv sib cuag hlau. Nws yuav paub qhov rov qhib thiab kaw ntawm qhov hloov pauv los ntawm deforming thaum nias thiab rov qab mus rau nws lub xeev qub thaum tso tawm.

Txhim khu kev sib cuag kev ua tau zoo: Los ntawm kev txo qis kev tiv thaiv thiab muab kev sib cuag tsis tu ncua, daim ntawv tiv tauj hlau tuaj yeem lav qhov kev sib cuag hluav taws xob zoo ob qho tib si thoob plaws hauv kev nias thiab tso tawm haujlwm.

Kev xaiv khoom

Cov khoom siv: Cov ntaub ntawv sib tiv tauj hlau feem ntau siv rau hauv kev sib tiv tauj tiaj tus muaj xws li stainless hlau, tooj liab alloy, npib tsib xee alloy, thiab nyiaj-plated hlau. Kev xaiv ntawm cov ntaub ntawv sib txawv nyob ntawm qhov chaw siv thiab kev ua haujlwm.

Stainless hlau: Nws muaj kev tiv thaiv corrosion zoo thiab elasticity thiab feem ntau siv hauv cov keyboards hauv qhov chaw hnyav.

Tooj alloy: Nws muaj cov conductivity zoo heev thiab feem ntau siv nyob rau hauv lub sij hawm xav tau siab conductivity.

Nyiaj los yog kub-plated tiv tauj daim: Cov khoom sib cuag nrog cov hlau muaj txiaj ntsig rau saum npoo yog cov khoom siv hluav taws xob ntau dua thiab tuaj yeem tiv thaiv oxidation zoo, ua rau lub neej ua haujlwm ntev.

Cov qauv thiab cov qauv

Pav ca tsim: Rau kev siv hauv cov tshuab hloov me me, cov khoom sib txuas ncaj nraim feem ntau yog ua los ntawm cov khoom nyias nyias. Qhov kev tsim no tsim nyog rau cov khoom siv hluav taws xob uas xav tau kom txuag tau qhov chaw vim tias nws tuaj yeem ua kom nyias nyias qhov kev hloov tag nrho.

Poob tsim: Txhawm rau lav qhov chaw me me thaum kov, qee qhov chaw sib cuag tau ua nrog cov pob me me ntawm lawv qhov chaw. Qhov no txo qis kev tiv thaiv kev tiv thaiv thiab ua rau kom muaj kev vam khom kev sib cuag.

Stamping: Cov txheej txheem ntawm stamping hlau tiv tauj daim yields heev npaum li cas thiab cov duab raws li ib tug tej yam elastic rov qab quab yuam.

Peb Cov Kev Pabcuam

Xinzhe Hlau Khoom Co., Ltd. yog ib tug ua ntawv hlau fabricator nyob rau hauv Suav teb.

Laser txiav, hlau txiav, stamping, dabtsi yog khoov, thiab vuamyog cov txheej txheem tseem ceeb.

Cov thev naus laus zis tseem ceeb siv hauv kev kho saum npoo yogsandblasting, electrophoresis, electroplating, anodizing, thiab txau.

Cov khoom tseem ceeb muaj xws li steel qauv connectors, seismic brackets, kab hlau rhuav phab ntsa,ruaj khov, txuas brackets, kem brackets, of elevator guide rails,qhia rail brackets, tsheb brackets, counterweight brackets, tshuab chav tsev khoom brackets, qhov rooj kaw lus brackets, tsis brackets, of elevator rail clamps,qhia rail txuas daim hlau, bolts thiab ceev, expansion bolts, caij nplooj ntoos hlav washers, tiaj tus ntxhua khaub ncaws, xauv lub tshuab ntxhua khaub ncaws, rivets, pins thiab lwm yam khoom siv hauv tsev. Peb muab customized accessories rau ntau hom of elevator rau ntiaj teb no hom xws liSchindler, Kone, Otis, ThyssenKrupp, Hitachi, Toshiba, Fujita, Conley, Doverthiab lwm tus.