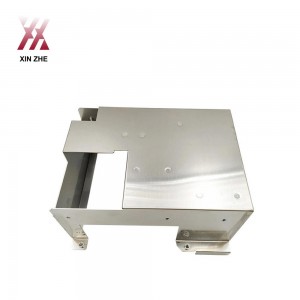

Factory pheej yig kub Hight Quality Laser Txiav Kev Siv Siab Siab tsis sib xws zaus Screw Cua Compressor

Ua rau theem ntawm kev npau suav ntawm peb cov neeg ua haujlwm! Txhawm rau tsim kom muaj kev zoo siab, sib koom ua ke ntau dua thiab ntau pab neeg tshwj xeeb! Txhawm rau kom ncav cuag cov txiaj ntsig zoo ntawm peb cov neeg siv khoom, cov chaw muag khoom, lub neej thiab peb tus kheej rau Hoobkas Pheej Yig Kub Hight Zoo Laser Txiav Siv Lub Siab Hloov Pauv Hloov Siab Nrawm Ntsia Hlau Cua Compressor, Peb tam sim no tau xa tawm mus rau ntau tshaj 40 lub teb chaws thiab cheeb tsam, uas tau txais lub koob npe zoo heev los ntawm peb cov neeg siv khoom txhua qhov chaw hauv ntiaj teb.

Ua rau theem ntawm kev npau suav ntawm peb cov neeg ua haujlwm! Txhawm rau tsim kom muaj kev zoo siab, sib koom ua ke ntau dua thiab ntau pab neeg tshwj xeeb! Txhawm rau kom ncav cuag cov txiaj ntsig ntawm peb cov neeg siv khoom, cov chaw muag khoom, lub zej zog thiab peb tus kheej rauTuam Tshoj Cua Compressor thiab Permant Magnet, Cov khoom tau dhau los ntawm kev lees paub lub teb chaws tsim nyog thiab tau txais txiaj ntsig zoo hauv peb txoj kev lag luam loj. Peb pab pawg kws tshaj lij engineering feem ntau yuav npaj los pab koj rau kev sab laj thiab tawm tswv yim. Peb tseem tuaj yeem xa koj nrog tus nqi kuaj dawb kom ua tau raws li koj cov specs. Cov kev siv zog zoo tshaj plaws yuav raug tsim los muab cov kev pabcuam thiab cov kev daws teeb meem zoo tshaj plaws rau koj. Xav tau koj xav tau peb lub tuam txhab thiab cov kev daws teeb meem, koj yuav tsum hu rau peb los ntawm kev xa email rau peb lossis hu rau peb ncaj qha. Yuav kom paub txog peb cov kev daws teeb meem thiab kev lag luam. ntau, koj tuaj yeem tuaj rau peb lub Hoobkas kom pom nws. Peb yuav tos txais qhua los ntawm thoob plaws lub ntiaj teb no mus rau peb lub tuam txhab. o tsim kev lag luam kev lag luam. kev xav nrog peb. Nco ntsoov tias muaj kev ywj pheej hais lus rau peb rau lub koom haum. nd peb ntseeg tias peb yuav qhia qhov zoo tshaj plaws trading tswv yim kev nrog tag nrho peb cov tub lag luam.

Kev piav qhia

Kev piav qhia

txheej txheem vuam

1. Electrode arc vuam:

Electrode arc welding yog ib qho kev siv arc vuam uas siv phau ntawv tuav ntawm electrodes rau vuam. Yog li ntawd, qhov zoo ntawm cov vuam yog nyob ntawm tus welder kev khiav hauj lwm tshuab, uas yuav tsum tau tus welder kom paub ntau dua kev khiav hauj lwm kev txawj ntse.( vuam ntawv hlau / vuam nyias hlau / tig vuam daim hlau)

2. Submerged arc vuam (tsis siv neeg vuam):

Submerged arc welding (xws li submerged arc surfacing thiab electroslag surfacing, thiab lwm yam) yog ib txoj kev vuam uas cov arc hlawv hauv qab txheej txheej. Nws cov txiaj ntsig zoo xws li cov vuam zoo zoo, cov khoom siv vuam zoo, tsis muaj lub teeb arc thiab cov pa luam yeeb me me ua rau nws txoj kev vuam tseem ceeb hauv kev tsim cov hlau tseem ceeb xws li cov hlab ntsha siab, cov yeeb nkab seem, thiab lub thawv kab teeb.

3. Cov pa roj carbon dioxide shielded vuam (tsis siv neeg lossis semi-automatic vuam):

Cov pa roj carbon dioxide shielded welding yog ib hom kev siv vuam, uas siv cov pa roj carbon dioxide los ua cov roj tiv thaiv kev vuam. Nyob rau hauv cov nqe lus ntawm daim ntawv thov, nws yog ib qho yooj yim rau kev khiav lag luam thiab yog haum rau tsis siv neeg welding thiab tag nrho-round welding. Yuav tsum tsis muaj cua thaum vuam, haum rau kev ua haujlwm sab hauv tsev.( tig vuam nyias hlau / zoo tshaj plaws vuam rau nyias hlau / vuam ntawv

Soldering ceev faj

1. Qhov ntev ntawm lub arc (khoov steel mov)

Qhov ntev ntawm lub arc muaj feem xyuam rau hom electrode txheej thiab thickness ntawm txheej. Txawm li cas los xij, luv luv arcs yuav tsum tau siv ntau npaum li qhov ua tau, tshwj xeeb tshaj yog qis-hydrogen electrodes. Qhov ntev arc yuav ua rau porosity. Qhov luv luv arc tuaj yeem tiv thaiv O2, N2 thiab lwm cov pa phem hauv huab cua los ntawm kev cuam tshuam cov hlau hlau, tsim cov khoom tsis zoo xws li oxides thiab cuam tshuam rau qhov zoo ntawm qhov vuam.( vuam aluminium ntawv hlau / hlau dabtsi yog khoov)

2. Vuam ceev (khoov hlau)

Qhov tsim nyog vuam ceev yog nyob ntawm cov kev hloov pauv hauv cov xwm txheej xws li txoj kab uas hla electrode, txheej txheej, vuam tam sim no, lub peev xwm ntawm cov khoom yuav tsum tau welded, thiab qhov pib ntawm cov qauv, thiab tsis tuaj yeem teev nyob rau hauv cov qauv. Tuav lub vuam nrawm nrawm, thiab cov slag tuaj yeem npog lub pas dej molten zoo. Ua kom muaj ntau yam impurities thiab gases nyob rau hauv lub molten pas dej ua ke muaj lub sij hawm txaus los ntab tawm, thiab zam qhov tsim ntawm slag inclusions thiab pores nyob rau hauv lub weld. Yog hais tias qhov ceev ntawm kev txav tus pas nrig yog ceev heev thaum lub sij hawm vuam, lub shrinkage kev nyuaj siab yuav nce thaum lub vuam qhov txias, ua rau tawg nyob rau hauv lub weld.

Cov ntsiab lus tseem ceeb rau kev xaiv vuam hlau (laser txiav thiab khoov cov kev pab cuam nyob ze kuv)

Kev xaiv ntawm vuam hlau yuav tsum yog raws li hom hlau yuav tsum tau welded, qhov yuav tsum tau zoo ntawm welded qhov chaw, vuam siv tej yam kev mob (phaj thickness, zawj puab, vuam txoj hauj lwm, vuam tej yam kev mob, tom qab vuam thaum tshav kub kub kho thiab vuam ua hauj lwm tos), nqi thiab lwm yam kev xav.( dabtsi yog khoov stainless hlau / dabtsi yog khoov txhuas ntawv / nias)

Ua rau theem ntawm kev npau suav ntawm peb cov neeg ua haujlwm! Txhawm rau tsim kom muaj kev zoo siab, sib koom ua ke ntau dua thiab ntau pab neeg tshwj xeeb! Txhawm rau kom ncav cuag cov txiaj ntsig zoo ntawm peb cov neeg siv khoom, cov chaw muag khoom, lub neej thiab peb tus kheej rau Hoobkas Pheej Yig Kub Hight Zoo Laser Txiav Siv Lub Siab Hloov Pauv Hloov Siab Nrawm Ntsia Hlau Cua Compressor, Peb tam sim no tau xa tawm mus rau ntau tshaj 40 lub teb chaws thiab cheeb tsam, uas tau txais lub koob npe zoo heev los ntawm peb cov neeg siv khoom txhua qhov chaw hauv ntiaj teb.

Hoobkas pheej yig kubTuam Tshoj Cua Compressor thiab Permant Magnet, Cov khoom tau dhau los ntawm kev lees paub lub teb chaws tsim nyog thiab tau txais txiaj ntsig zoo hauv peb txoj kev lag luam loj. Peb pab pawg kws tshaj lij engineering feem ntau yuav npaj los pab koj rau kev sab laj thiab tawm tswv yim. Peb tseem tuaj yeem xa koj nrog tus nqi kuaj dawb kom ua tau raws li koj cov specs. Cov kev siv zog zoo tshaj plaws yuav raug tsim los muab cov kev pabcuam thiab cov kev daws teeb meem zoo tshaj plaws rau koj. Xav tau koj xav tau peb lub tuam txhab thiab cov kev daws teeb meem, koj yuav tsum hu rau peb los ntawm kev xa email rau peb lossis hu rau peb ncaj qha. Yuav kom paub txog peb cov kev daws teeb meem thiab kev lag luam. ntau, koj tuaj yeem tuaj rau peb lub Hoobkas kom pom nws. Peb yuav tos txais qhua los ntawm thoob plaws lub ntiaj teb no mus rau peb lub tuam txhab. o tsim kev lag luam kev lag luam. kev xav nrog peb. Nco ntsoov tias muaj kev ywj pheej hais lus rau peb rau lub koom haum. nd peb ntseeg tias peb yuav qhia qhov zoo tshaj plaws trading tswv yim kev nrog tag nrho peb cov tub lag luam.