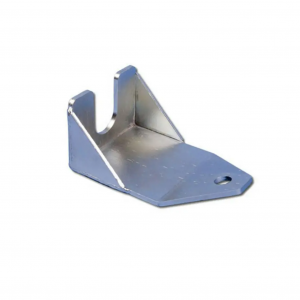

Auto Parts Tsheb Pem Hauv Ntej Npog Pob khawm Folding Support Bracket Original Accessories

Kev piav qhia

| Yam khoom | customized khoom | |||||||||||

| One-Stop Service | Pwm txoj kev loj hlob thiab tsim-xa cov qauv-batch ntau lawm-kev tshuaj xyuas-nto kho- ntim-xa. | |||||||||||

| Txheej txheem | stamping, dabtsi yog khoov, sib sib zog nqus daim duab, ntawv hlau fabrication, vuam, laser txiav thiab lwm yam. | |||||||||||

| Khoom siv | carbon steel, stainless hlau, txhuas, tooj liab, galvanized hlau thiab lwm yam. | |||||||||||

| Qhov ntev | raws li tus neeg siv khoom kos duab lossis qauv. | |||||||||||

| Ua kom tiav | Txau painting, electroplating, kub-dip galvanizing, hmoov txheej, electrophoresis, anodizing, blackening, thiab lwm yam. | |||||||||||

| Daim ntawv thov cheeb tsam | Nws pib qhov chaw, ua liaj ua teb machinery qhov chaw, engineering machinery qhov chaw, kev tsim engineering qhov chaw, vaj accessories, ib puag ncig tus phooj ywg machinery qhov chaw, nkoj qhov chaw, aviation qhov chaw, yeeb nkab fittings, kho vajtse cuab yeej qhov chaw, khoom ua si qhov chaw, hluav taws xob qhov chaw, thiab lwm yam. | |||||||||||

Qhov system zoo

Tag nrho peb cov chaw muaj ntawv pov thawj ISO 9001.Tsis tas li ntawd, Xinzhe muaj kev paub dhau los hauv kev tswj xyuas zoo thiab cov txheej txheem thoob plaws ntau lub lag luam thiab cov ntawv thov tshwj xeeb.

Cov Txheej Txheem Kev Pom Zoo Ntau Lawm

Tswj Plan

Hom Failure and Effects Analysis (FMEA)

Measurement Systems Analysis (MSA)

kev kawm thawj zaug

Statistical Process Control (SPC)

Peb lub chaw soj nstuam zoo kuj tsim cov tshuab calibration xws li CMMs thiab optical comparors mus rau hardness test.Tiv tauj peb kom paub ntau ntxiv.

Kev tswj kom zoo

Vickers hardness ntsuas.

Profile ntsuas ntsuas.

Spectrograph ntsuas.

Peb qhov kev sib koom tes.

Daim duab xa khoom

Txheej txheem ntau lawm

01. Pwm tsim

02. Pwm ua

03. Hlau txiav ua

04. Pwm kho cua sov

05. Pwm sib dhos

06. Pwm debugging

07. Deburring

08. electroplating

09. Kev kuaj khoom

10. Pob

Tuam txhab Profile

Ningbo Xinzhe Hlau Khoom Co., Ltd., raws li ib tug stamping sheet hlau tsum nyob rau hauv Tuam Tshoj, tshwj xeeb nyob rau hauv zus tau tej cov tsheb qhov chaw, ua liaj ua teb machinery qhov chaw, engineering machinery qhov chaw, siv engineering qhov chaw, kho vajtse accessories, environmentally friendly machinery qhov chaw, nkoj qhov chaw, aviation qhov chaw, yeeb nkab fittings, cuab yeej kho vajtse, khoom ua si accessories, hluav taws xob accessories, thiab lwm yam.

Los ntawm kev sib txuas lus nquag, peb tuaj yeem nkag siab zoo txog lub hom phiaj kev lag luam thiab muab cov lus qhia muaj txiaj ntsig los pab txhawb peb cov neeg siv khoom lag luam, uas muaj txiaj ntsig zoo rau ob tog.Txhawm rau kom yeej qhov kev ntseeg siab ntawm peb cov neeg siv khoom, peb tau cog lus los muab cov kev pabcuam zoo thiab cov khoom zoo.Tsim kom muaj kev sib raug zoo mus ntev nrog cov neeg siv khoom uas twb muaj lawm thiab nrhiav cov neeg siv khoom yav tom ntej hauv cov teb chaws uas tsis yog koom tes los pab txhawb kev sib koom tes.

Hlau stamping txheej txheem tsim

Hlau stamping yog txheej txheem nyuaj uas yuav suav nrog ntau yam txheej txheem hlau - blanking, xuas nrig ntaus, khoov thiab xuas nrig ntaus, thiab lwm yam.

Blanking: Cov txheej txheem no suav nrog kev txiav cov qauv ntxhib lossis cov duab ntawm cov khoom.Lub hom phiaj ntawm theem no yog kom txo qis thiab tsis txhob burrs, uas tuaj yeem ua rau tus nqi ntawm cov khoom thiab ncua sij hawm xa tuaj.Cov kauj ruam no yog txhawm rau txiav txim siab lub qhov taub, geometry / taper, ntug rau qhov sib nrug thiab qhov twg los ntxig cov punch thawj.

dabtsi yog khoov: Thaum koj tsim khoov rau hauv stamped hlau qhov chaw, nws yog ib qho tseem ceeb uas yuav tsum tau tso cov khoom txaus ib sab - xyuas kom tseeb tias koj tsim ib feem thiab nws qhov khoob kom muaj cov khoom txaus los ua qhov khoov.

Punching: Qhov kev ua haujlwm no yog thaum cov npoo ntawm cov hlau stamped yog tapped kom flatten los yog tawg tawm burrs;qhov no tsim smoother npoo nyob rau hauv cam khwb cia cheeb tsam ntawm ib feem geometry;qhov no kuj ntxiv dag zog ntxiv rau thaj chaw hauv cheeb tsam ntawm ib feem, thiab tuaj yeem siv kom tsis txhob muaj kev ua haujlwm thib ob xws li deburring thiab sib tsoo.