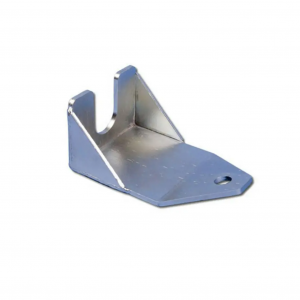

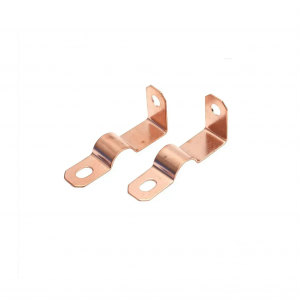

u zoo li lub caij nplooj ntoos hlav clip, caij nplooj ntoos hlav steel fasteners clip, tuav clips

Kev piav qhia

| Yam khoom | customized khoom | |||||||||||

| One-Stop Service | Pwm txoj kev loj hlob thiab tsim-xa cov qauv-batch ntau lawm-kev tshuaj xyuas-nto kho- ntim-xa. | |||||||||||

| Txheej txheem | stamping, dabtsi yog khoov, sib sib zog nqus daim duab, ntawv hlau fabrication, vuam, laser txiav thiab lwm yam. | |||||||||||

| Khoom siv | carbon steel, stainless hlau, txhuas, tooj liab, galvanized hlau thiab lwm yam. | |||||||||||

| Qhov ntev | raws li tus neeg siv khoom kos duab lossis qauv. | |||||||||||

| Ua kom tiav | Txau painting, electroplating, kub-dip galvanizing, hmoov txheej, electrophoresis, anodizing, blackening, thiab lwm yam. | |||||||||||

| Kev thov cheeb tsam | Auto Parts, Agricultural Machinery Parts, Engineering Machinery Parts, Siv Engineering Parts, Garden Accessories, Eco-friendly Machinery Parts, Nkoj Yam, aviation Parts, Pipe Fittings, Hardware Tool Parts, Toy Part, electronics, etc. | |||||||||||

Qhov zoo

1. Ntau tshaj 10 xyoontawm kev lag luam txawv teb chaws.

2. Muabib-stop servicelos ntawm kev tsim pwm mus rau kev xa khoom.

3. Lub sijhawm xa khoom sai, txog30-40 hnub.Hauv Tshuag hauv ib lub lis piam.

4. Kev tswj xyuas nruj thiab tswj cov txheej txheem (ISOcertified chaw tsim tshuaj paus thiab Hoobkas).

5. Ntau tus nqi tsim nyog.

6. Kev tshaj lij, peb lub Hoobkas muajntau tshaj 10xyoo ntawm keeb kwm nyob rau hauv lub tshav pob ntawm hlau stamping sheet hlau.

Kev tswj kom zoo

Vickers hardness ntsuas.

Profile ntsuas ntsuas.

Spectrograph ntsuas.

Peb qhov kev sib koom tes.

Daim duab xa khoom

Txheej txheem ntau lawm

01. Pwm tsim

02. Pwm ua

03. Hlau txiav ua

04. Pwm kho cua sov

05. Pwm sib dhos

06. Pwm debugging

07. Deburring

08. electroplating

09. Kev kuaj khoom

10. Pob

Txoj Kev Stamping

Hlau stamping yog txheej txheem tsim khoom uas cov coils lossis cov ntawv tiaj tus ntawm cov khoom raug tsim rau hauv cov duab tshwj xeeb.Stamping encompasses ntau yam txheej txheem xws li blanking, xuas nrig ntaus, embossing, thiab nce tuag stamping, hais txog ob peb yam.Cov khoom siv ob qho tib si ntawm cov txheej txheem no los yog ntawm nws tus kheej, nyob ntawm qhov nyuaj ntawm daim.Nyob rau hauv tus txheej txheem, dawb paug coils los yog nplooj ntawv tau txais mus rau hauv ib tug stamping xovxwm uas siv cov cuab yeej thiab tuag los tsim nta thiab nto nyob rau hauv cov hlau.Hlau stamping yog ib txoj hauv kev zoo tshaj plaws los tsim ntau qhov chaw, los ntawm lub tsheb qhov rooj thiab lub zog rau cov khoom siv hluav taws xob me me siv hauv xov tooj thiab khoos phis tawj.Stamping txheej txheem yog heev-tau txais nyob rau hauv automotive, industrial, teeb pom kev zoo, kho mob, thiab lwm yam lag luam.

Brass Tooling Cheebtsam

Xinzhe Hlau Stampings pab cov neeg siv khoom thoob plaws hauv lub tebchaws nrog cov khoom siv hlau zoo, ua siab ntev.Ua qhov chaw ntawm cov cuab yeej ib txwm muaj thiab cov txheej txheem tsis raug, peb cov kev pabcuam tooj dag hlau stamping muaj xws li: Blanking Bending, Forming, Piercing, Coining.

Xinzhe Hlau Stampings yog ISO 9001 tau ntawv pov thawj vim peb tsim kev tswj xyuas zoo thiab kev cog lus rau kev ua tau zoo ntawm txhua theem ntawm txoj haujlwm.Peb cov neeg koom tes ua lag luam tau txais txiaj ntsig los ntawm peb qhov kev mob siab rau ua kom tau raws li cov neeg siv khoom xav tau thiab cov qauv kev cai lij choj, uas ua rau kev ua haujlwm zoo tshaj plaws thiab ua kom cov khoom zoo.Yog xav paub ntxiv txog peb precision tooj dag forging thiab tooj dag hlau stamping cov kev pab cuam, hu rau peb tam sim no.